Precision-Engineered Automated Robotics Solutions

Solutions 4 Automation specializes in custom-engineered automation services for industrial robotics applications.

From precision CNC machine control systems to streamlined automation solutions for robotic loading and component assembly, we deliver innovative engineering services that optimize the production capacity of your business for quality, consistency and cost-effectiveness.

Custom Robotics & Machine Automation Solutions for Industrial Assembly & Material Handling Applications

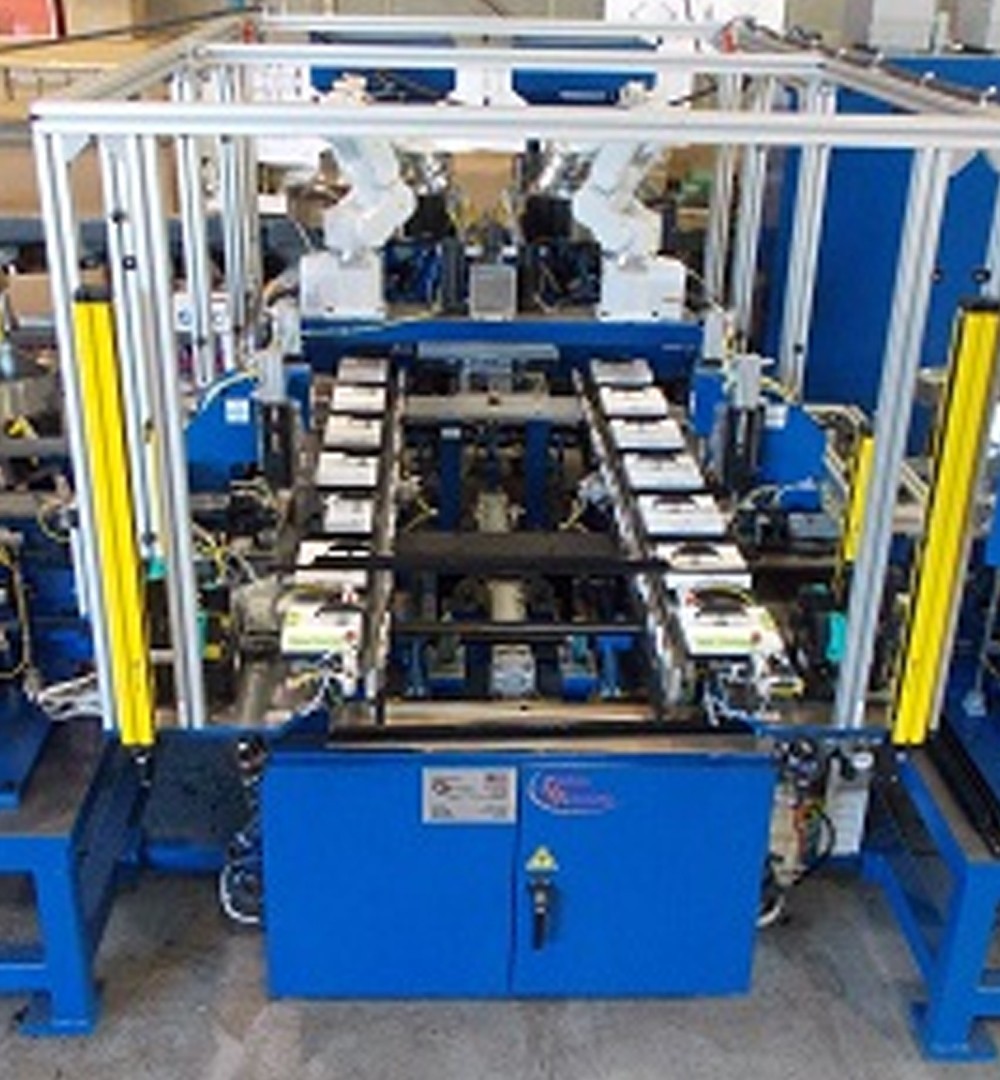

Robotic Door Trim Assembly Machine

S4A designed and built an automated Robotic Door Trim Assembly machine for automotive component production. It features a manual load and automatic unload system, as well as an eight-station walking beam transfer utilizing Epson-manufactured robots for automated assembly operations.

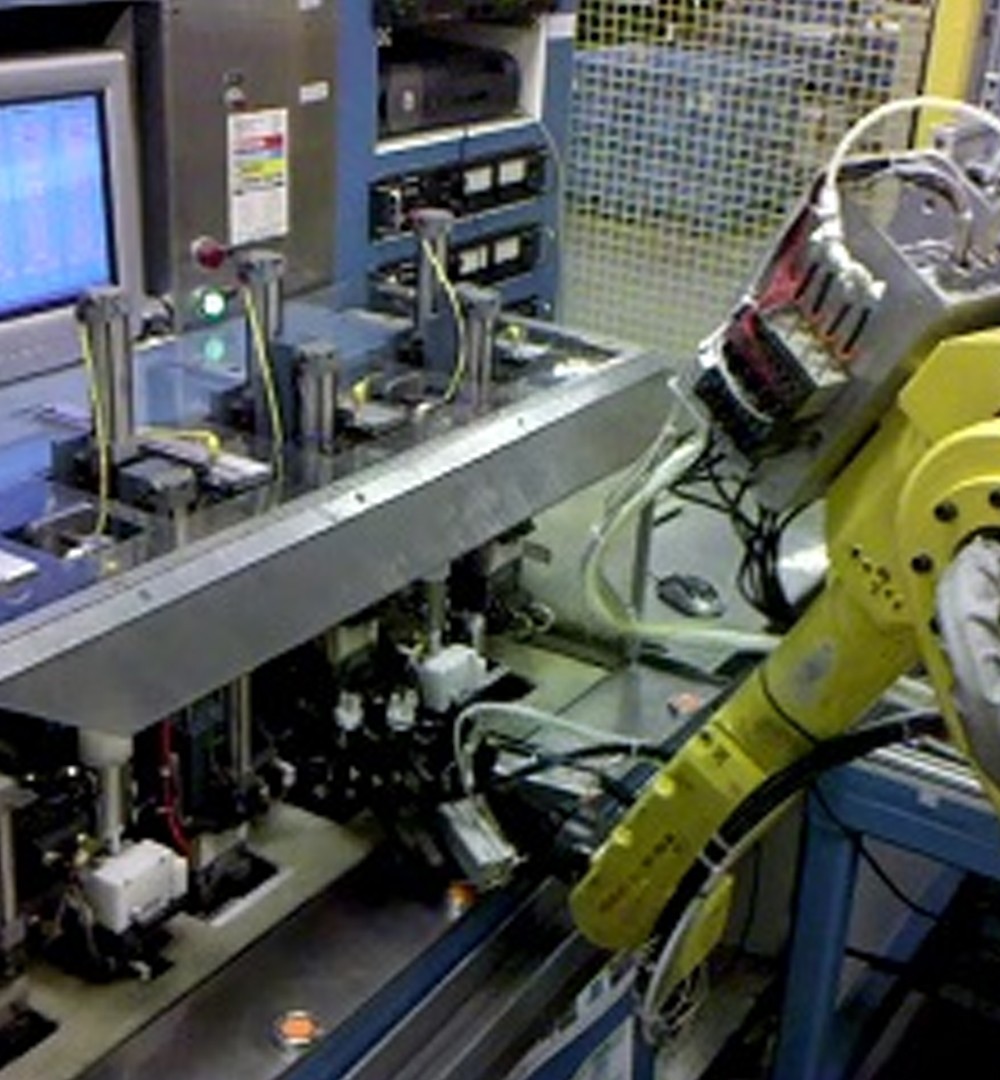

Robotic Casting Sand Blast Cell

S4A engineered and manufactured a custom system for handling aluminum engine blocks during post-process sand blasting operations. It has automated load/unload capabilities and a specialized material handling cell utilizing three Fanuc M-900 Series robots for precision component handling operations.

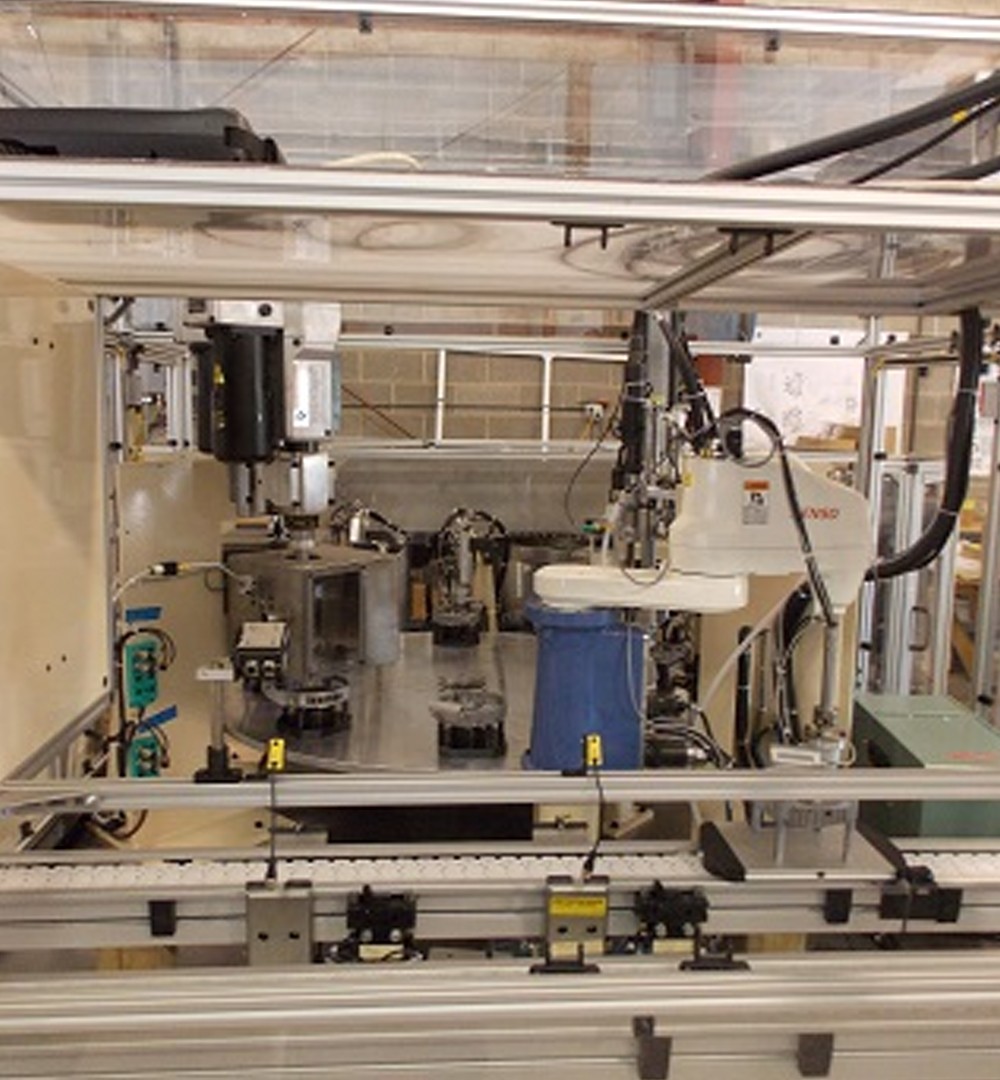

CMM Integration with CNC Autocomp

S4A designed and built a precision quality inspection machine to streamline the quality control process with automated efficiency. This custom product testing and inspection system features robotic load/unload capabilities and dual-station CMM part inspection stations. It utilizes Denso robots and Mitutoyo CMM units programmed with S4A-designed automatic in-process offsets for a Fanuc-controlled CNC Machine.

Robotic Dial Assembly Machine

S4A engineered and built a custom automated dial assembly machine integrating a multitude of manufacturing processes. Includes a Denso robotic load/unload capability and features an eight-station dial assembly machine utilizing a roll-form tapping station, Smart Press, screw feed / torque and Denso robot handling systems.

Robotic Auto Load

S4A integrated a custom robotic auto load system to change a machine from manual load to automatic load. This automated loading system utilizes Fanuc robots with precision end of arm tooling to deliver optimized production results through decreased cycle time and increased system throughput. System also included OSHA approved perimeter safety guarding.

Robotic Lathe Load

S4A integrated a precision robotic material handling system to de-palletize recreational vehicle brake hubs with auto load/unload into lathes chucks. This automated material handling cell utilizes Fanuc robots for streamlined production precision and repeatability.

Streamlined Automation Engineering for Turnkey Robotics Systems

The expert engineering team at S4A draws upon decades of combined innovation to deliver the most effective turnkey robotics automation solutions in the industry. From automated assembly and custom CNC machine programming to robotic material handling systems, we engineer superior turnkey robotics functionality optimized for a range of industries and processes.

Equipment Types

- Lean Manufacturing Systems

- Turnkey Assembly & CNC Systems

- Dial Assembly Machines

- Smart Press Assembly

- Robotic Automation

- In-process & Post-process Testing and Gauging

- Leak Test Fixtures & Machines

- Function Test Machines

- Custom Material Handling Systems

- Dispense Application Systems

- Barcode & Vision Process and Inspection Applications

- Fixtures

Product Experience

- Steering Columns, Rack & Pinion Assembly and Test

- Electric Actuator Assembly & Test

- Alternators

- Cameras

- Brake Systems

- Starters

- Fuel Pump Assembly Test

- Fuel Tank Rollover Check Valve Assembly Test

- Tank Assembly and Test

- Flying Cut-off Machines

- Stator Assembly & Test

- Shower & Bath Assembly

- Mattress Assembly