Streamlined Automation Solutions for Industrial Assembly Machines

Solutions 4 Automation delivers innovative engineering services for automated assembly machines and other industrial manufacturing systems. Our cutting-edge automation solutions include lean assembly, dial assembly, and other specialized assembly systems.

A sample of the different assembly machine processes and projects that Solutions 4 Automation has delivered to our diverse range of industrial customers are highlighted below.

Automated Lean Assembly Machines

Insulator Ring-to-Stator Assembly Press Machine

S4A designed and built the Servo Press Machine, Conveyor Load/Unload and a Single Station Machine.

Jacket Servo Press Machine

S4A designed and built Machine-to-Press Bearings for a Jacket Assembly. We utilized three different Cognex cameras for barcode scanning, error proofing and post-process gauging. S4A designed a Force vs. Distance Graphing and Data Acquisition System.

Dimple Press Machine

S4A designed and built Machine-to-Press for two parts simultaneously. We utilized air-over-oil cylinders.

Friction Process Spin Welder

S4A refurbished Machine-to-Friction Weld Fittings for plastic tubing with orientation and critical process tracking that includes a graphing capability. S4A replaced Siemens with a new Omron control system.

Dial Assembly Machines

Laser Marker Dial Machine

S4A designed a Build-to-Print Laser Marking Dial Machine. It has manual load, auto unload utilizing a 4-Station Dial Assembly Machine with KEYENCE laser markers.

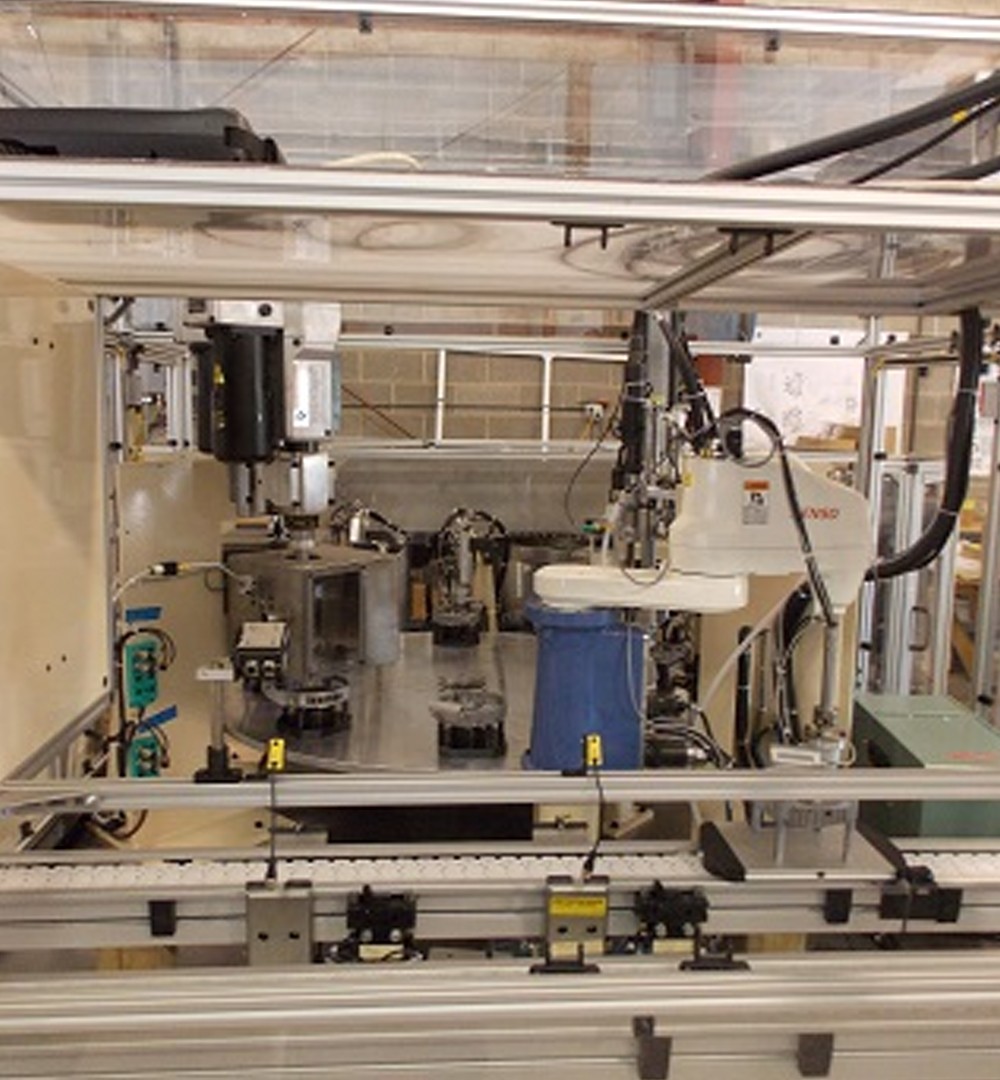

Robotic Dial Machine

S4A designed and built the Robotic Dial Machine. It has robotic load/unload and an 8-Station Dial Assembly Machine utilizing roll form tapping, Smart Press, screw feed & torque and Denso robots.

6-Station Dial Machine

S4A designed and built the 6-Station Dial Machine. It has manual load/unload and a 6-Station Dial Assembly Machine utilizing feeder bowls, KEYENCE gauging and air-over-oil press.

Brake Hose Fitting Assembly Dial Machine

S4A’s flood recovery rebuild of a Brake Hose Fitting Assembly Dial Machine. It has auto load/unload and an 8-Station Dial Assembly Machine utilizing feeder bowls and O-ring installation.

Assembly Systems

Robotic Door Trim Assembly Machine

S4A designed and built a Robotic Door Trim Assembly Machine. It has manual load, auto unload and an 8-Station Walking Beam Transfer utilizing Epson Robots for assembly operations.

Flying Cut-Off Machine

S4A designed and built a Flying Cut-Off Machine to continuously cut moving material off a de-reeler to a pre-programmed product length. It incorporates a Speed Compensating Laser Encoder and an Integrated Automatic Die Changing capability.

Lean Assembly Cell

S4A designed and built the Lean Assembly Cell (with rail-mounted, moveable End Station with flexibility to run from 6 to 22 Stations). It has flexible line balancing to match operators with production requirements and also incorporates smart, quick-change Fixture Pallets for multiple product platforms with RFID traceability.

Balance Machine

S4A Mechanical and Controls rebuild of a Hydraulic BEL Balance Machine providing improved cycle time and throughput and machine performance and new data acquisition capability for traceability.

Servo Press Machine

S4A designed and built the Servo Press Machine incorporating the S4A custom-designed Live Force vs. Distance Graphing and Data Acquisition System.