Test Machines

Automated Quality Control Solutions for Precision Industrial Test Machines

Solutions 4 Automation specializes in engineering innovative solutions for industrial product testing, automated inspection and quality control. From custom automated CNC machine solutions to hydraulic function testing and leak test machines, we have the expertise to engineer the precision test equipment that streamline the quality control capabilities of your business.

Custom-Engineered Automation for Precision Leak Test Machines

Viscous Clutch Leak Test Machine

S4A designed and built a Clutch Leak Test Machine. It has manual load/unload and a Single Station Machine utilizing a Uson Leak Tester.

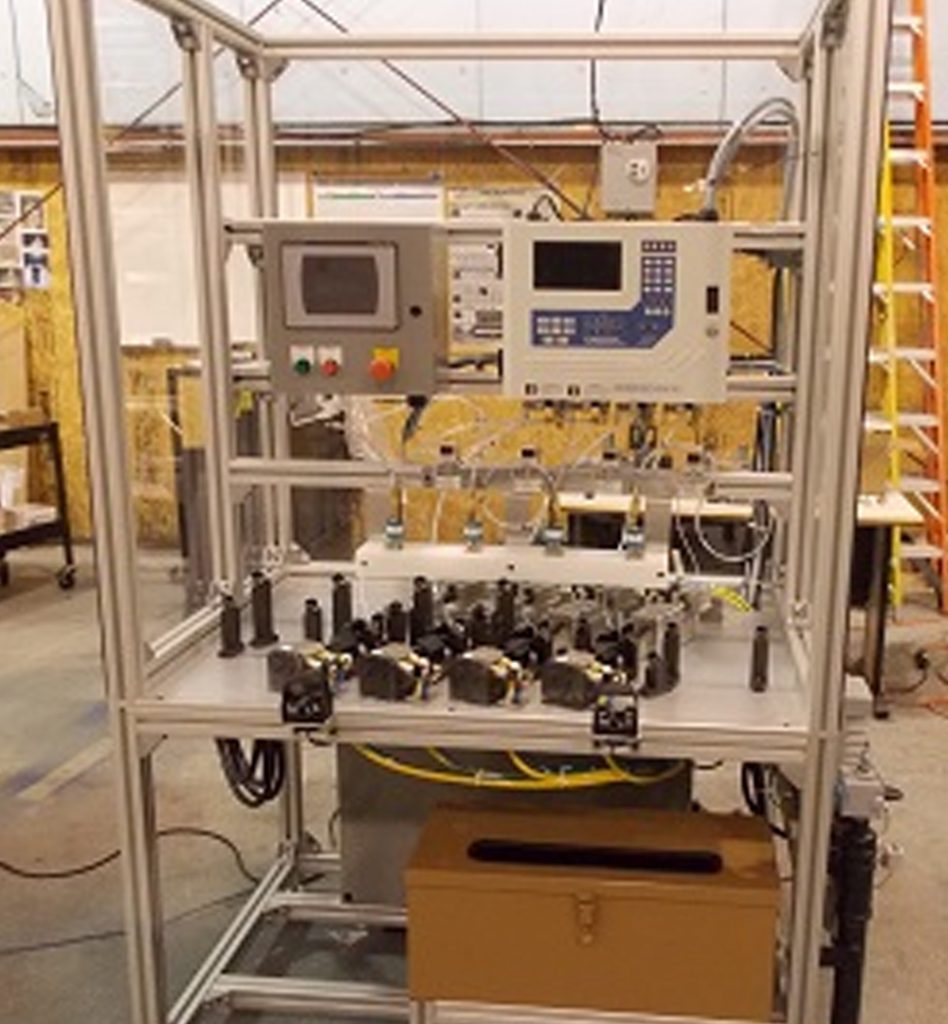

4-Station Break Line Leak Test Machine

4-Station Break Line Leak Test Machine

S4A designed and built a 4-Station Break Line Leak Test Machine to test four assemblies simultaneously. It has manual load/unload and a Single Station Machine utilizing a Multi-channel Cincinnati Test Systems Leak Tester.

Function Test

Hydraulic Valve Test

Hydraulic Valve Test

S4A designed and built a machine to perform function tests on a Hydraulic Valve Assembly. We utilized our S4A Custom-Designed Data Acquisition System to report test results directly to a plant database system and incorporated a Dapra Pin Stamp System for post-process traceability.

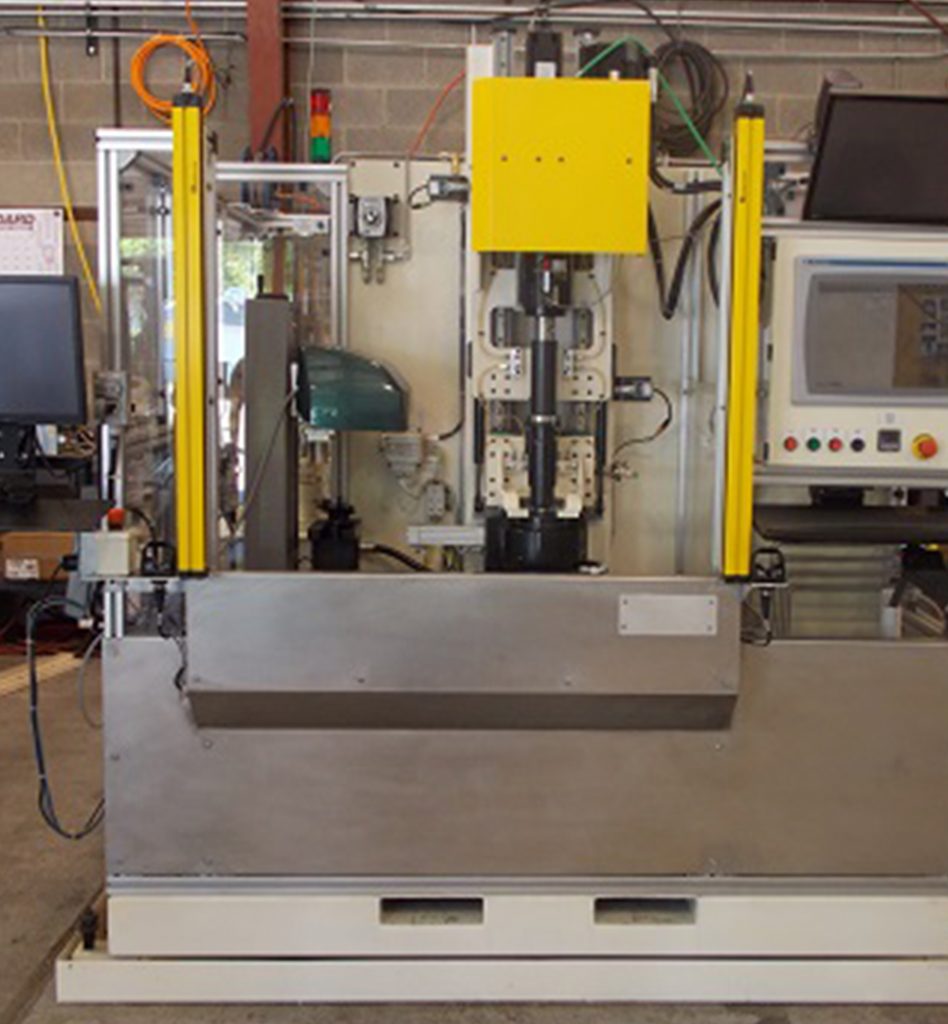

Hydraulic Burst Test

Hydraulic Burst Test

S4A designed and built a machine to perform a Hydraulic Destruction Test. It captures peak pressure where an assembly fails testing.

Gauging & Inspection

Auto Checker Machine

S4A designed and built a machine to measure seven Critical Alternator Shaft features. It has auto load/unload, a 10-Station Walking Beam Transfer and utilizes KEYENCE LVDT technology to measure diameters, taper locations and hole depths. This system also included dimensional feedback to the CNC for auto comp input.

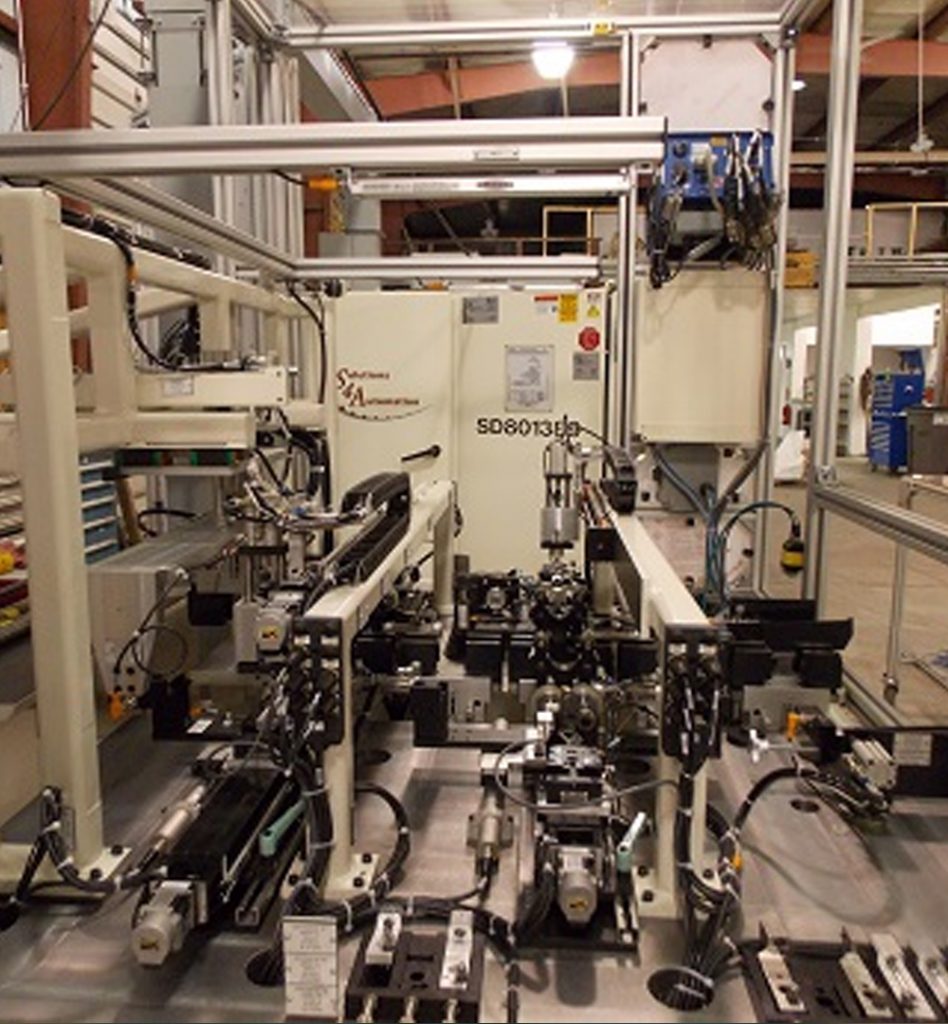

Eddy Current Inspection Machine

Eddy Current Inspection Machine

S4A designed and built a machine to Inspect for Surface and crack Imperfections on smooth and spline shafts (both OD and ID). It has auto load/unload and a 6-Station Walking Beam. Transfer utilizing an integrated Criterion Eddy Current Controller and Probes.

CMM Integration with CNC Autocomp

CMM Integration with CNC Autocomp

S4A designed and built an Inspection Machine. It has robotic load/unload and a Dual Station CMM Machine that utilizes Denso Robots and Mitutoyo CMM Machines with an S4A-designed Automatic Offset to a Fanuc Controlled CNC Machine.

Vision

Cognex System Integrator

Cognex System Integrator

S4A has been certified as a Cognex System Integrator and we proudly use Cognex cameras for all types of Machine Vision applications.

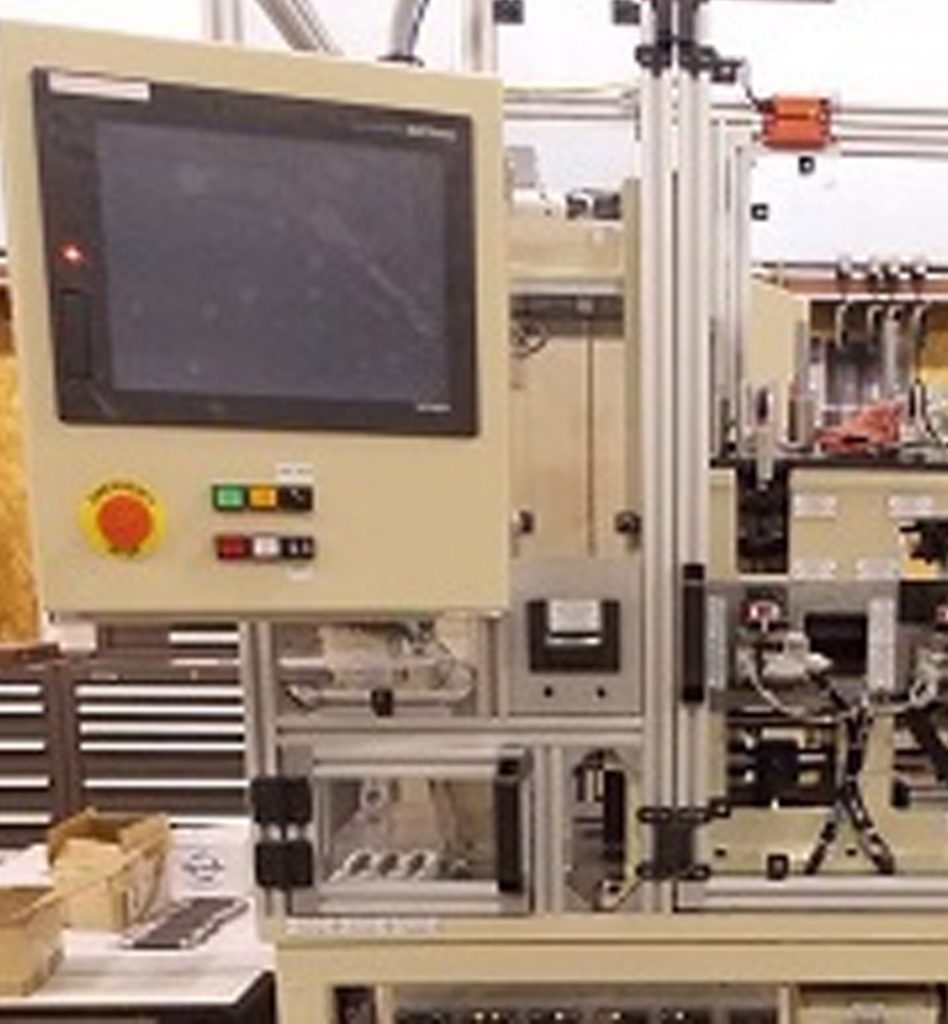

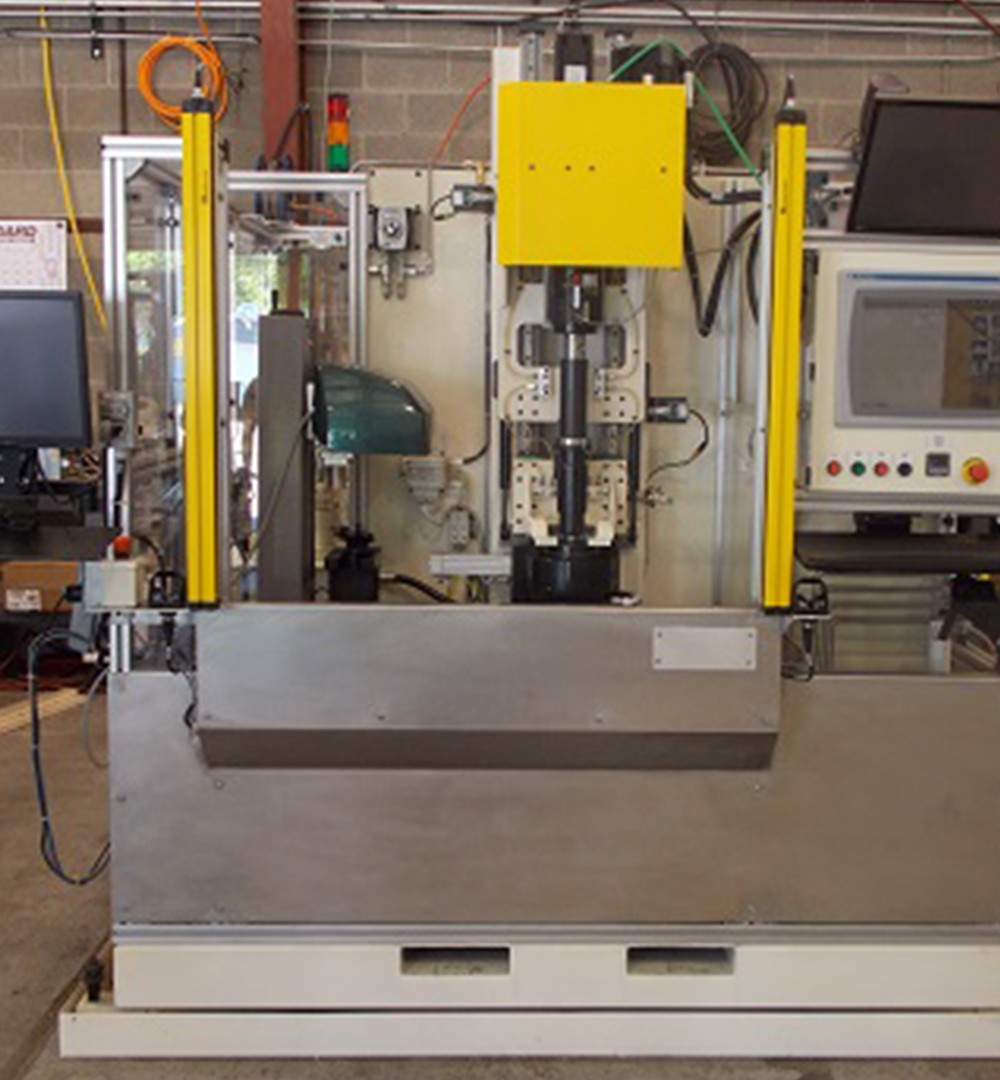

Jacket Press Machine

Jacket Press Machine

S4A designed and built Machine-to-Press Bearings for a Jacket Assembly. We utilized three different Cognex cameras for barcode scanning, error proofing and post-process gauging. In addition, we incorporated an S4A-designed Force vs. Distance Graphing and Data Acquisition System.

Jacket Press Machine

Jacket Press Machine